HOW CAN BAMBOO CONTRIBUTE TO THE CIRCULAR ECONOMY?

4 December 2019 – Plastic pollution, climate change and deforestation: a number of the world’s most pressing global challenges can be traced to the extractive, ‘take, make, waste’ nature of current economic growth.

In recent years, the idea of a ‘circular economy’ has been gaining traction, in response to concerns about our linear models of production and consumption. A radical new concept for sustainable growth, the circular economy involves designing products, services and supply chains which are regenerative: that is, which are based on renewable energy and resources, do not generate waste, and keep products and materials in use for as long as possible.

Ideally, products in the circular economy would be biologically based, and quickly renewable. This is where bamboo can play a major role. A new report, commissioned by INBAR, shows how a number of bamboo products can make an important contribution to more circular living.

The report, Bamboo in the Circular Economy, finds that bamboo could be a critical component in the transition to more circular production. This fast-growing grass plant can be used to create a wide range of both durable and consumer products, which substitute those from man-made materials.

Specifically, the authors show how:

-

Bamboo is rapidly self-regenerating. It grows fast, can be harvested without the need to replant, and matures quickly, within 3 to 5 years, to a hard, wood-like material, with a diverse range of uses. In circular economy terms, bamboo’s fast growth means that it can regenerate within the period of most products’ lifespan – making it a ‘renewable’ resource.

-

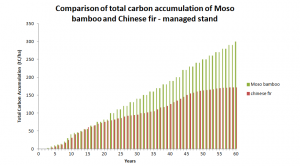

Bamboo can store more carbon than certain species of tree. Bamboo stores carbon in living biomass as well as durable bamboo products. Because bamboo regenerates so quickly, over a period of time a bamboo plantation can lock carbon within a larger number of products than can most kinds of tree, making it an important carbon sink.

Accumulation of carbon comparison between moso bamboo and Chinese fir over time. (INBAR 2015)

-

Industrial bamboo products can be a renewable, low-carbon alternative to traditional materials. As well as storing carbon, bamboo can avoid carbon by substituting emissions-intensive materials. Durable bamboo products, such as flooring, cladding, decking, and primary and secondary construction material, have a similar performance but far lower carbon footprint than many common building materials, including steel, aluminium and PVC. This is despite the resins, laminates and glues which are used in bamboo products’ creation.

Carbon footprint over lifecycle for various common building materials. Credit: MaterialDistrict

-

Bamboo can also substitute plastic. Bamboo is already being used in a wide range of goods with a shorter lifespan, typically under five years: from single-use bags, straws, crockery, cups and cutlery, to more durable products, including telephone and laptop cases, watches, glasses, kitchen items, sports articles and health and beauty products. Although less critical to the circular economy than their durable counterparts, which can replace abiotic materials for a long period of time, a number of these products can still make an important contribution to the circular economy.

-

At the end of their lifespan, bamboo products can be repurposed, recycled or burned as energy. If a bamboo product is built using entirely bio-based components, it can be repurposed into new products and eventually recycled; products which include glue or laminates are converted into charcoal, pellets and gas, for use as biomass energy.

Although these products have important potential to contribute to the circular economy, the report identifies are a number of obstacles to their integration. In particular, the use of non-bio-based resins, glues and artificial preservatives in engineered bamboo materials and composites can make products unfit to upcycle or recyle; these products must instead by burned for energy at the end of their life, which is a relatively unproductive use within the circular economy. Other products, such as bamboo textiles, can be chemically intensive to produce. These current limitations are often not made clear by companies, which market bamboo goods as a ‘green’ alternative, without a serious attempt at creating a 100% biobased product.

The authors provide a number of recommendations for the further integration of bamboo products into a circular economy:

-

The search for bio-based alternatives to synthetic parts in bamboo products, including resins, glues and laminates, will make a critical difference to bamboo products’ fit in a circular economy. Research is already underway, and important innovations – such as the development of bio-based resins, and Lyocell fabrics – are being made. Once cost-competitive, these technologies will dramatically improve bamboo products’ circular potential.

-

Companies must be transparent and set development goals to reach the 100% bio-based target for their products.

-

Policy makers and companies must focus on developing an integrated bamboo industry, which adds value to the full bamboo resource.

-

There is an important opportunity for the bamboo sector to take advantage of climate crediting schemes. The extra funding and policy support offered by these schemes could spur the development of the sector, and increase the feasibility of establishing even more bamboo plantations and forests worldwide.

In a foreword to the report, sustainability expert and author of The Blue Economy, Gunter Pauli, praised the importance of bamboo, saying: “I am convinced that there will be no real sustainability… unless we turn bamboo into an integral part of our economy.

“It is now high time to inspire policy makers, business and financial lears to deploy all opportunities of circularity offered by bamboo.”

The report can be accessed on INBAR’s library. It can be cited as: van der Lugt, P., King, C. (2019) Bamboo in the Circular Economy. INBAR Policy Synthesis Report 6. Beijing, China: INBAR.